For some reason I find these things fascinating, so I've started some more projects that I'll probably never ever finish.

There are a lot of really good projects out there for learning FPGA's and some really good stuff rebuilding retro computers.

Two I've taken an interest to are the

MIST and the

MEGA65. Mainly because I am a child of the 70/80's and grew up in an age when you could really understand how your computer really worked.

Now I haven't got a clue about HDL ( VHDL or Verilog ) so I'm really just stuffing about but if you can get yourself the required hardware to run the cores here are my notes on how to build them on the latest ( at the time of writing ) Ubuntu distribution. Which surprisingly wasn't that hard to do.

This was all done in Vmware workstation 12.

Installing Xilinx 14.7 and Compiling the MEGA65 Core

1) Get Ubuntu Desktop 17.04

https://www.ubuntu.com/download/desktop

Do a default install.

2) Install everything in ~/Documents

cd ~/Documents

mkdir MEGA65

cd MEGA65

3) Install git, libpng-dev

sudo apt-get install git

sudo apt-get install libpng-dev

3) Get git repositories required

git clone https://github.com/MEGA65/mega65-core.git

git clone https://github.com/gardners/Ophis.git

git clone https://github.com/sasq64/cbmconvert.git

4) Compile and install cmbconvert

cd ~/Documents/MEGA65/cbmconvert

make -f Makefile.unix

sudo make install

5) Download Xilinx 14.7 WebPACK

https://www.xilinx.com/support/download/index.html/content/xilinx/en/downloadNav/design-tools.html

As I wish to use both Windows and Linux I got this file :

Full DVD Single File Download Image (TAR/GZIP - 7.78 GB)

6) Create an account and get a FREE Webpack License

https://www.xilinx.com/registration/sign-in.html?oamProtectedResource=wh%3Dwww.xilinx.com%20wu%3D%2Fmember%2Fforms%2Flicense-form.html%20wo%3D1%20rh%3Dhttp%3A%2F%2Fwww.xilinx.com%20ru%3D%252Fmember%252Fforms%252Flicense-form.html

OR

Wait until after the install

7) Install Xilinx 14.7

cp Xilinx_ISE_DS_14.7_1015_1.tar ~/Documents/

cd ~/Documents

tar xvf Xilinx_ISE_DS_14.7_1015_1.tar

cd ~/Documents/Xilinx_ISE_DS_14.7_1015_1

sudo ./xsetup

Accept multiple license agreements

Choose ISE WebPACK from Edition List

Don't install cable drivers . . .

Install to default /opt/Xilinx

You can remove Xilinx_ISE_DS_14.7_1015_1.tar and Xilinx_ISE_DS_14.7_1015_1.tar as they are no longer needed.

8) Start ISE for the first time and add your license ( or get one )

. /opt/Xilinx/14.7/ISE_DS/settings64.sh

ise

9) Add settings to your .bashrc so it is available every time you log in and/or start a terminal

cd ~

vi .bashrc

Add this line to the end of the file

. /opt/Xilinx/14.7/ISE_DS/settings64.sh

10) Compile the mega65 core

cd ~/Documents/MEGA65/mega65-core

./compile.sh

11) Wait . . . this took about 53 minutes in the VM. However the resulting core worked perfectly

Installing VMware Tools

1) Add source code to the list of Source repositories

Click on the Ubuntu Icon and type Software, then click on "Software & Updates"

Under the TAB Ubuntu Software, check the "Source Code" checkbox

While you are there also pick a repository close to you, preferrably one you can get free downloads from

in the "Download from:" Dropbox.

2) Install the source code

apt-get source linux-image-$(uname -r)

3) Unzip and untar the tools and run the installer picking ALL of the default options

cp VMwareTools-10.1.6-5214329.tar.gz /tmp

cd /tmp

gzip -d VMwareTools-10.1.6-5214329.tar.gz

tar xvf VMwareTools-10.1.6-5214329.tar

cd vmware-tools-distrib/

./vmware-install.pl

ALTERA Quartus II 13.1 - for the MIST

0) Get Altera Quartus II 13.1

http://dl.altera.com/13.0sp1/?edition=web

I got the Linux version, it's 4.5GB in size.

1) You will need to install the 32 bit version of the system libraries

sudo bash

dpkg --add-architecture i386

apt-get update

apt install apt-file # We need to find 32 bit packages

apt-file update # so use apt-file to search

apt-file seach <package> # for them

apt-get install libc6:i386 # Not too sure about the first 3

apt-get install libstdc++6:i386 #

apt-get install expat:i386 #

apt-get install libfreetype6:i386 # But you definitely need these ones

apt-get install libsm6:i386 #

apt-get install libxrender1:i386 #

apt-get install libfontconfig1:i386 #

apt-get install libxext6:i386 #

2) Get a really old version of libpng12 both 32 and 64 bit.

Because you can't symlink the new version and have it work as the Qt library it uses looks

at the version number in the library.

http://packages.ubuntu.com/xenial/amd64/libpng12-0/download

http://packages.ubuntu.com/xenial/i386/libpng12-0/download

dpkg -x libpng12-0_1.2.54-1ubuntu1_i386.deb outfiles

cd outfiles/lib

cp * /usr/lib/i386-linux-gnu/

dpkg -x libpng12-0_1.2.54-1ubuntu1_amd64.deb outfiles54

cd outfiles/lib/x86_64-linux-gni

cp * /usr/lib/x86_64-linux-gnu/

3) Make a directory and untar the installer

mkdir Altera

cd Altera

tar xvf Quartus-web-13.1.0.162-linux.tar .

4) Edit the setup file and change the first line From

#!/bin/env bash

To

#!/bin/bash

5) Open a new terminal

xhost + # Not sure about this as the graphical installer didn't work anyhow

sudo bash

./setup.sh

6) It will go to the command line installer

Press Enter lots

Then hold down Enter for the agreement

Then choose Y

Then choose a new directory : /op/altera/13.1

Then choose the defaults ( basically install the Free stuff )

Wait . . .

Do defaults

7) Start Quartus II

Now both versions run:

cd /opt/altera/13.1/quartus/bin

./quartus # for 32 bit

./quartus --64bit # for 64 bit

Compile the MIST C64 Core

1) Download and Compile C64 core for mist

cd ~/Documents

mkdir C64

cd C64

git clone https://github.com/sorgelig/C64_MIST.git

2) Start Quartus II

Open Project and Compile

It takes about 3mins 41 secs

~/Documents/C64/C64_MIST/output_files/C64_mist.rbf

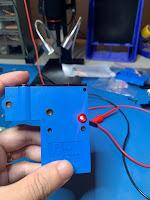

The only thing that fixed it was to follow step 2 correctly with the wiring.

Ensure that you are using the +5V and NOT +3.3V

Tie pin 1(GND) and 7(FORMAT) together and connect to Ground

Tie pin 2(RES) and 11(+5V) together and connect to +5V

Pin 9 (D0) goes to RX on the Arduino

Pin 10 (LED) should go to an appropriate resistor, LED then Ground.